CIPP vs. Slip Lining: A Comprehensive Guide for Expanding Your Plumbing Business

Trenchless pipe repair is a huge market opportunity today. The growing market is slated to reach $3.8B by 2030, and now is the time to invest if you’re a plumbing company looking to expand your business into new revenue opportunities.

Slip lining is one of the oldest trenchless repair methods, but modern methods like CIPP lining have some important advantages over older options. We’re guiding you through the benefits, drawbacks, and best-use scenarios for these two methods.

What You’ll Learn:

CIPP lining offers a versatile solution for almost any pipe repair need, while slip lining provides a more economical repair option in limited scenarios.

Slip lining is better suited for larger municipal projects with straight runs, while CIPP lining is ideal for residential and multifamily repairs with more complex bends and connections.

Repair companies that focus on residential, commercial, and multifamily markets benefit more from CIPP lining, while companies that focus on large-scale and budget-focused work may prefer slip lining.

Trenchless pipe repair is easy to add to your plumbing business when you have the right training, materials, equipment, and support.

Time to Expand Your Plumbing Business: Why CIPP Lining is a Smart Investment

If you want to grow your plumbing business, trenchless is an ideal starting point. And with CIPP repairs, you could find yourself filling your calendar with new business opportunities in no time.

What Is CIPP and How Does It Work?

CIPP repair is the leading technology for trenchless repairs. CIPP lining starts with a resin-saturated felt liner. The liner is inserted into the host pipe, then pressed against the interior walls of the pipe using water or air pressure. The resin then cures, creating a new pipe within the old pipe in just a few short hours. And with UV curing systems, the process can be done in less than 2 hours.

The flexible, customizable resin liner allows pipe repair companies to tackle almost any pipe issue.

No More Excavation

Instead of digging trenches for the entire length of the broken pipe, CIPP repair allows techs to complete almost all repair work without lifting a single shovel. That’s less disruption for commercial jobs, less rehab for residential jobs, and less frustration for every customer.

Lightning-Fast Installation

Downtimes go from days to hours with trenchless pipe repair. CIPP repair leads the charge against weeks-long downtimes and disruptions. Ambient curing can take 12 hours or less, while hot water and steam curing drop the time down to just 4 hours on average.

But if you need even faster jobs, UV curing systems like T3’s SpeedyLight system can take as little as 90 minutes from start to finish.

The rough translation for businesses? You can triple your available calendar spots easily without expanding your staffing needs.

Cleaner, Smaller Workspaces

Both residential and commercial customers hate losing their spaces to repairs. Homeowners and renters want their living spaces back to normal as soon as possible. Retail and industrial jobs want minimal disruption so they don’t lose revenue. CIPP repairs serve both purposes incredibly well.

Multi-Market Applications

While most CIPP repair businesses focus on residential and commercial sewer line repairs, cured-in-place repairs work well for several markets, as well as unique applications within specific markets. From industrial and manufacturing waste to oil and gas pipelines, CIPP is ready for high-throughput, high-pressure, and corrosive applications just as much as municipal water supply, commercial lines, and multifamily properties.

Structural Integrity and Flexibility

A key advantage for CIPP is its installation capabilities. Instead of a rigid pipe, CIPP starts with a flexible resin liner that can navigate bends and provide custom lengths and designs to accommodate complex pipe systems. It’s easy to install and easy to reinstate in almost any pipe.

Once cured, CIPP liners act structurally the same as a brand-new pipe. It’s an ideal solution for pipes that risk collapsing in the near future, as well as pipelines located under heavy substrates.

Understanding Your Options: When Does Slip Lining Fit Your Services?

While CIPP comes with many advantages, alternatives like slip lining may be a better option for specific situations. The technique predates CIPP lining, but its simplicity offers some important advantages.

What is Slip Lining and How Does It Work?

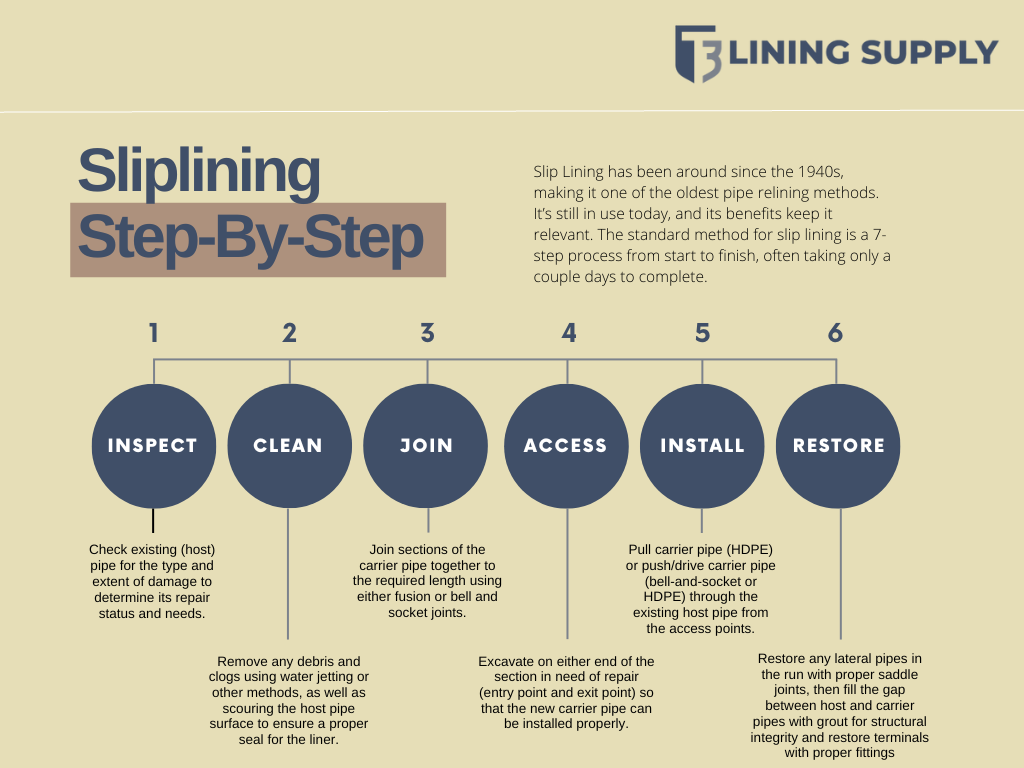

Slip Lining has been around since the 1940s, making it one of the oldest pipe relining methods. It’s still in use today, and its benefits keep it relevant. The standard method for slip lining is a 7-step process from start to finish, often taking only a couple of days to complete.

Inspect the Pipe: check the host pipe to assess damage, build up, or other issues that should be considered prior to starting the installation.

Clean the Pipe: using water jetting or pigging to clean out clogs, debris, build up, and obstructions. The host pipe needs to be thoroughly cleaned to guarantee a proper seal between the host and carrier pipes.

Join the Carrier Pipes: join sections of the carrier pipe together to meet the required length of the repair.

Access the Existing Host Pipe: Excavate at the entry and exit points of the repair.

Install the Liner: Either push or pull the carrier pipe through the host pipe, depending on the carrier pipe’s material and joint type (HDPE can be pushed or pulled, but bell-and-spigot joint pipes need to be pushed to keep a watertight seal).

Restore Lateral Connections: after the 24-hour relaxing period, reconnect any lateral pipes with saddles.

Restore Terminal Connections: Stabilize the carrier pipe within the host pipe by filling the gap with grout. After the grout is cured, reconnect the existing terminals to the host pipe with appropriate fittings.

In most cases, slip lining can take a couple of days to complete, considerably shortening the timeframe from conventional trenching repairs. Still, it takes much longer than most CIPP repairs.

Specific Scenarios Where Slip Lining Excels

Cost-Conscious Repairs: Slip lining tends to be less expensive than both conventional methods and some trenchless methods.

Large-Diameter Pipes: Non-residential pipelines with large diameters can handle slip lining well without losing too much throughput volume.

Extended Lifespan: Since slip lining places an entirely new pipe inside the host pipe, you can expect 50-100 years of additional service.

Less Digging: When infrastructure and buildings need to remain untouched, slip lining offers an economical solution with less digging and trenching than conventional methods. There is still some excavation necessary for access; however, this limits its application in some scenarios.

CIPP vs. Slip Lining: Making the Right Choice for Your Plumbing Services

Choosing between CIPP and slip lining largely depends on the types of repairs you’ll encounter in your market. Let’s look at the most important factors for maximizing your ROI.

Key Considerations for Your Business Growth

Pipe Diameter: Do your typical jobs involve large or small pipes? (CIPP for small, slip lining for large)

Damage Severity: Do you deal more often with minor leaks or major breaks requiring structural support? (CIPP for severe damage, slip lining for minor to moderate, where host pipe supports)

Downtime & Customer Convenience: How critical is minimal service disruption for your clientele? (CIPP is faster, less invasive)

Cost vs. Convenience for Clients: Which priority resonates more with your target customers? (Slip lining is cheaper, CIPP offers premium convenience)

Pipe Geometry: Are straight runs common, or do you encounter many curves and bends? (CIPP for curves, slip lining for straight runs)

Repairing Minor Leaks & Damage

Both CIPP and slip lining repairs work for minor leaks and nonstructural damage, but pipe diameter is a deciding factor on which method is better. CIPP is better suited for small diameter pipes (down to 2”), while slip lining can restrict volume too drastically at smaller diameters.

Tackling Major Breaks & Structural Integrity

CIPP repair has a clear advantage with more severe structural damage. So long as the pipe is not collapsed, CIPP repairs can rehabilitate it. Slip lining relies more on the host pipe’s own structural integrity, so it’s not a strong choice in these cases.

Sewer Line Repair: Maximizing Convenience & Efficiency

Slip lining, although considered a trenchless repair, still requires more excavation than CIPP lining to access the pipe. Sewer repairs with CIPP are less invasive, getting residents and businesses back to normal with less rehab work. But when cost is a significant factor, slip lining may win out simply for its affordability.

| Slip Lining | CIPP Lining | |

|---|---|---|

| Excavation free | ✔ | |

| Short downtime | ✔ | ✔ |

| Sewer line repairs | ✔ | ✔ |

| Light to moderate damage | ✔ | ✔ |

| Large diameter pipes | ✔ | |

| Small diameter pipes | ✔ | |

| Severe damage | ✔ | |

| Curves and bends | ✔ |

Realizing the ROI: Why CIPP is the Future for Plumbing Companies

Let’s talk business: your investment in trenchless tech needs fast return to make sense. If you’re comparing slip lining and CIPP, you’ll see quickly that today’s markets favor cured-in-place solutions for rapid returns and long-term business benefits.

A Growing Market and Quick Returns

CIPP is one of the most versatile trenchless repair methods. While originally designed for agricultural uses, it’s proven its ability to solve residential and multifamily pipe problems without costly digging or long service downtimes. CIPP is the go-to for sewer line repairs, especially in urban and suburban areas.

With that versatility, your calendar can fill up quickly, making it possible for the equipment investment to pay for itself in just a few short months. And advancements like UV curing are making CIPP repairs even more convenient, economical, and environmentally friendly.

Overcoming Implementation Challenges with T3

If you’re ready to invest in CIPP lining, you’ll need more than just equipment to keep your business running smoothly.

Quality Equipment: T3 offers both top brands and fully customized equipment, helping your business find success from the first job.

Proven Materials: We benchmark all our resins and liners through third-party testing, giving you and your customers more confidence in your workmanship.

Customized Training: Our team of seasoned professionals helps your employees learn on your equipment or ours, and at the location that works best for you. We teach what you need to know instead of relying on cookie-cutter programs.

Live 24-7 Expert Customer Support: No call centers, no pre-recorded messages, and no clueless customer service reps. When you call T3’s emergency help line, you get a real expert ready to walk you through any challenge you encounter, no matter what time you call.

Business Planning and Marketing: Our experts can help you figure out pricing, market opportunities, and business-building tips. Our blog is also full of helpful tools and tips for better business planning and growth.

Frequently Asked Questions

What is the ROI of adding CIPP services for a plumbing company?

CIPP offers a quick return on investment, especially for residential and multifamily services, due to faster completion times, less invasive work, and high market demand.

Is CIPP difficult for plumbers to learn and implement?

T3 provides the necessary technology, comprehensive training, and materials to ensure a smooth adoption process, making it accessible for plumbing companies.

What types of jobs are best suited for CIPP lining?

Small diameter pipes (residential/multifamily), severe damage, pipes with curves/bends, and sewer lines where excavation needs to be avoided.

What types of jobs are best suited for slip lining?

Large diameter pipes (municipal and industrial), moderate damage, relatively straight runs, and anywhere excavation needs to be minimized.

Partner with T3 to Grow Your Plumbing Business

Trust T3 Lining Supply as your end-to-end CIPP lining business partner, with over 50 years of combined experience in trenchless technology. We’ll help you find the right solution for your company, the right training for your teams, and the right support to keep you moving forward.