Essential Equipment for CIPP Lining: How to Choose the 9 Tools You’ll Need

Updated April 7, 2025

Trenchless pipe lining repairs are a huge value add for your plumbing company. CIPP repairs can expand your market and improve your bottom line, but if you’re not getting the right equipment for the job, you could be risking big problems.

But don’t worry: we’ve got you covered. Here’s our expert guide to choosing the right equipment and materials for your trenchless repair business.

What CIPP Equipment Do You Really Need?

If you’re starting from scratch, your pipe repair business will need 9 essential tools and 3 types of materials to complete CIPP repairs. And while some of these tools and materials may differ depending on the method you’ll use, you’ll need one of each type regardless.

Essential Equipment for CIPP Lining

Inversion Drum

Cable Machine

Air Compressor

CCTV System

Calibrated Roller

Vacuum Pump

Descaling and Cleaning Tools

Curing Equipment

Finishing Tools

Essential Materials for CIPP Lining

Resin and Activators

Liners

Calibration Tubes

CIPP Installation Tools: Our Recommendations

Each step of the installation process requires different equipment and materials. We’ll break everything down here, including our personal recommendations for the equipment you should invest in.

Inspection and Cleaning

Equipment Needed: CCTV camera system, cable machine, descaling and cleaning tools

VIVAX CAMERA

Before any pipe can be repaired, you need to inspect the pipe to assess damage and intrusion. This is an opportunity to see what you’re up against, as well as a chance to determine if CIPP repair is the right solution for the job.

CCTV Camera System

This is your most important pre-installation tool, as well as your most important post-installation tool. Without a good CCTV camera, you won’t be able to assess the damage you’re planning to repair or the work you’ve completed.

Look for:

A portable system with a high-quality monitor

A long enough snake camera to complete your most common jobs PLUS several extra yards of length

Reliable training and support for the system so your techs know how to get the most out of it

Bonus Features:

System integrations to measure distance of the camera in the pipe

Cable Machine and Cleaning Tools

Your cable machine, or snake, allows you to clean the pipe before installation. You can attach descaling and cleaning tools to the snake, including chain knockers, brushes, sanding tools, and even hydrojetting heads (with the right snake system).

Look for:

The right length to complete your most common jobs PLUS a few extra yards

Cable guages that work with your pipe diameters

Tools that clean thoroughly without further damaging the pipe

Bonus Features:

Hydrojetting capabilities for alternative cleaning methods

Geolocation integrations for more precise cleaning

CIPP Lining Prep

Equipment Needed: Vacuum Pump, Calibrated Roller

Materials Needed: Pipe Liners, Resin

VACUUM PUMP

Prepping your liners for installation is critical. You need to watch temperatures, time, and resin ratios to get everything right. But that’s not all: you’ll also need to make sure your liners are saturated correctly and rolled out properly.

Vacuum Pump and Rollers

You don’t want air in your saturated liners, so you’ll need to vacuum them completely before impregnating them with the resin. After that, either manual or power rollers will help even out the distribution of the resin and ensure you can roll the liner into your inversion drum properly.

Look for:

Vacuum pumps that can handle continuous use

Low noise

Rollers with adjustable width settings for various calibration needs

Bonus Features:

Small footprints for more flexible workspace requirements

Foot-controlled electric rollers for faster and more accurate operation

Pipe Liners

While there are several different liner materials available, we find felt liners to be the most versatile while maintaining strength and consistency in installations.

Look for:

Single-layer construction

Variable material use (polyester, vinyl ester, non-styrene, and epoxy resins)

Bonus Features:

High tensile strength (750 psi)

Third-party testing and benchmarking

Resins

Your resins can make or break your installation success. The most common issues our clients encounter are resins that cure too quickly or too slowly due to temperature issues. Getting the right activator and resin is the best way to start your installation right.

Look for:

Base resins that can be mixed for different purposes

Variable cure time options (15, 30, and 60 minute cures)

Activators for colder temperatures

Bonus Features:

Low-styrene or non-styrene

UV-activated resins

CIPP Installation

Equipment Needed: Inversion Drum, Air Compressor

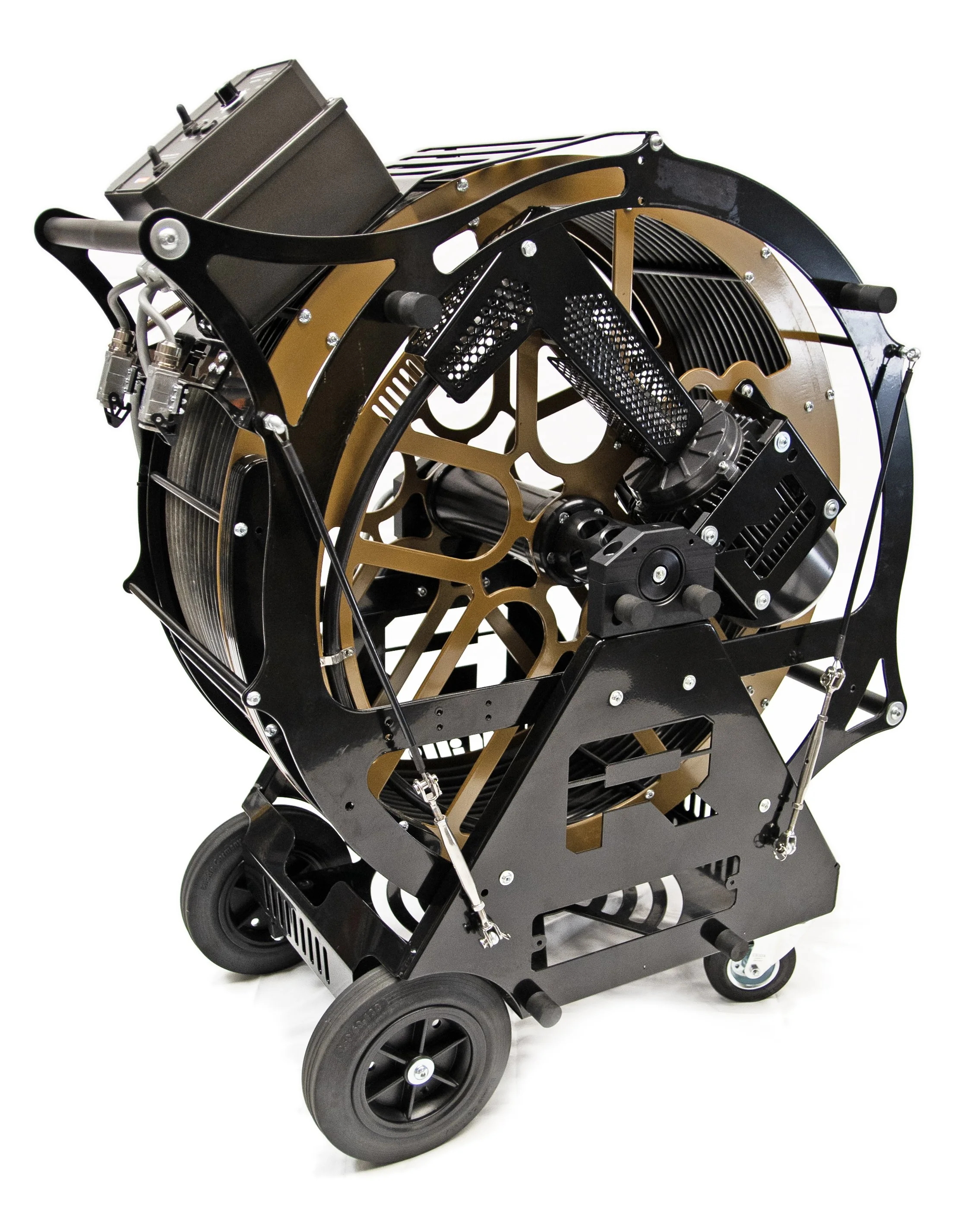

T3 INVERSION DRUM 400-S

With your liner prepped and calibrated, it’s time for installation. Your key tools at this stage are the inversion drum and air compressor.

Inversion Drum

Before you install the liner, the inversion drum acts as a storage container for your resin-saturated liner. It helps keep the temperature stable, reduces exposure to air, and also prevents UV resin from activating in sunlight. Once installation begins, it inverts your liner as it injects it into the host pipe via compressed air.

Look for:

A size that fits your needs (smaller drums for residential, larger drums for commercial)

Solid construction

Warranty and service plans

Ability to use air, hot water, and steam

Bonus Features:

Designed specifically for your resin and equipment manufacturer

Calibration adjustments for different installation types

Wheels for better mobility

Air Compressor

The air compressor works inline with the inversion drum to push the liner into the host pipe. Depending on your needs, you can choose air compressors based on size, capacity, or maximum pressure.

Look for:

Compatibility with your inversion drum

Easy-to-read guages

Adjustable pressure levels

Ability to maintain consistent pressures during installation

Bonus Features:

Small footprint

Lightweight construction

Quiet/silent operation

Curing

Equipment Needed: Calibration Tube, Manifold, Curing System

Curing equipment for CIPP lining is designed to provide temperature- and pressure-controlled conditions within the felt pipe liner while also allowing hot water, steam, or a UV lantern to pass through the liner. That takes a calibration tube, a manifold, and a curing system to complete.

Calibration Tubes and Manifold

These impermeable tubes allow your curing system to pressurize the liner, pressing it firmly against the host pipe while it cures. This pressure keeps the liner from delaminating and prevents air pockets between the old and new pipe walls. The manifold keeps the pressure consistent during the curing process by sealing the calibration tube for ambient cures or by allowing curing system components to be fed into the calibration tube without losing pressure.

Look for:

Various pressure and diameter options

Strong materials

Laminated seams tested for durability

Manifold should be compatible with your inversion system

Bonus Features:

UV-cure compatible materials (transparent)

Heat-tolerant materials for hot water and steam cure options

Curing Systems

Your curing system determines several different outcomes of your work. For the least expensive investment, ambient curing requires no extra equipment. But for faster curing with more consistent results, you can move to hot water, steam, or even UV curing systems. In each case, you’ll see clear benefits and drawbacks. And depending on the work you do, one system will likely outperform the others.

Factors to Consider:

Curing time: ambient cures can take several hours, while UV curing takes around 90 minutes

Initial investment: UV curing systems are by far the most expensive, but they can accelerate on-site work times

Typical work type: short-run work is perfect for hot cure systems, while industrial work may require more ambient curing

Finishing and Final Inspection

Equipment Needed: Cutting and Finishing Tools, CCTV System, Cable Machine

RCM-36

Part of the reinstatement process for CIPP repairs is cutting liner sections that cover terminals, laterals, and junctions. Leaving this step out could be costly to both you and the customer. By using your CCTV system and cutting tools, you’ll be able to reinstate repaired pipes without trouble.

Cutting and Finishing Tools

Manual cutting tools, connected to a cable machine, can help cut out the excess sections of the newly installed liner. But there are also robotic cutting tools available for more precise work. For finishing, you’ll want to sand down any rough edges so that there is no extra interference with flow, especially for sewer pipes.

Look for:

Tools compatible with your cable machine and CCTV system

Tools that offer clean cuts and smooth finishes

Bonus Features:

Robotic tools

Geolocation-guided tools and integrations for more accuracy and speed

Types of Curing Materials and Equipment for CIPP Lining

As we mentioned above, part of your equipment and process depends on the type of curing materials you use for your trenchless repairs. We offer three types of resins for various jobs. Here’s what you need to know.

Vinyl Ester Resin

This type of resin hardens with the addition of a powder activator. While it’s not as strong as epoxy resins, vinyl ester resins provide a reliable and waterproof solution for CIPP repairs. They are also less expensive than most other types of resins.

Two-Part Epoxy Resin

Two-part epoxy resins have been the standard for decades. You’ll start by mixing the resins, which triggers activation, using different hardeners for different cure speeds (15, 30, and 60), allowing for faster cures for cold temperatures and slower cures for hot temperatures.

T3 30 HARDENER

Epoxy resins like this can cure with ambient temperatures (usually around 77 degrees Fahrenheit) or with hot water or steam.

A hot water curing system can decrease your wait time significantly. Your boiler system circulates hot water through the calibration tube at temperatures between 140 degrees and 180 degrees throughout the curing process, which usually takes anywhere from 2 to 8 hours, depending on conditions and installation size.

UV-Activated Resin

For the fastest curing times, UV-activated resin is your go-to material. This type of resin hardens almost instantly (around 90 seconds) when exposed to UV light, with a full cure in around 90 minutes. By shortening the time it takes to complete a repair using UV resin materials and equipment for CIPP lining, you can offset the additional cost of this type of system through faster turnaround times.

Training Your Team on Pipe Lining Equipment the Right Way

When you’re ready to start working with CIPP lining equipment, you’ll want to provide your teams with industry-leading training. Extensive training allows you to repair any pipe with confidence. And that’s what we do at T3 Lining Supply.

We offer some of the best materials and equipment for CIPP lining in the industry, but we also provide leading-edge training opportunities that fit any need. You can bring your team to either of our locations, or we can come to you.

And if you already have the equipment, you can still train with us. We can help you get the most out of any equipment you use, even if it’s not something we sell.

But the hallmark of our business is our customer service. We provide 24-hour live assistance with one of our experts, from your first job to your 101st. If you have a challenge you can’t solve on your own, we’re ready to help.

Interested in CIPP lining equipment and training for your pipe repair or plumbing business? Contact us today to see how T3 can help you and your teams with industry-best trenchless pipe repair!