Slip Lining Versus CIPP Lining: What’s Right For Your Business?

Whether starting a new business or expanding your current company, trenchless pipe repair offers an excellent opportunity to add to your bookings. There are several options, and choosing the right service is key to success. In this article, we’re exploring two options: slip lining and CIPP lining. And when it comes to slip lining versus CIPP lining, you need to know all the details to make a confident—and profitable—choice for your business.

Slip Lining Versus CIPP Lining: What You Need to Consider

Both of these repair methods involve a less invasive solution to pipe repairs than the typical trenched repairs that most people are familiar with. But CIPP and slip lining each have specific markets that work best. When you’re choosing between the two, think about the following variables and how often your customers experience them:

Do you work with large or small pipe diameters?

Do your repairs require vertical runs or horizontal runs more often?

How long do you want your repairs to last?

How short do you want disruptions to service to last?

Are your customers more concerned about cost or convenience?

Will your repairs be hindered by restricting flow rates?

Once you have answers to these questions, read on to see what method works best for your repairs. Determining the benefits of slip lining versus CIPP lining for your business means determining your priorities and the requirements of your typical repair job.

How Slip Lining Works

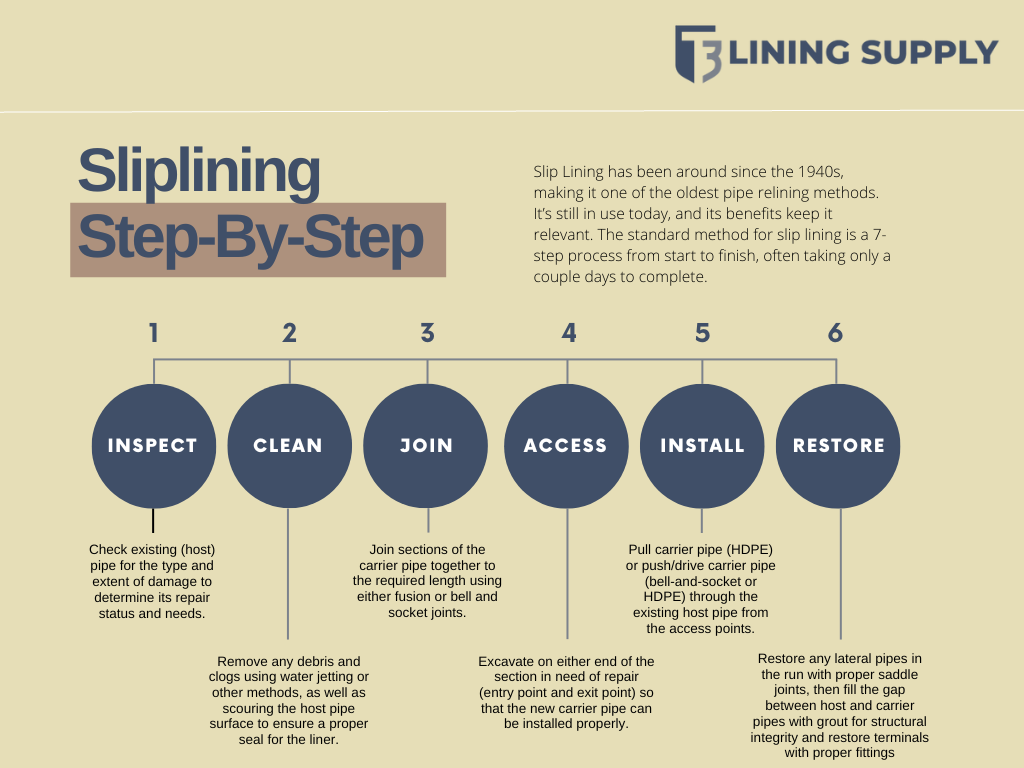

Slip Lining has been around since the 1940s, making it one of the oldest pipe relining methods. It’s still in use today, and its benefits keep it relevant. The standard method for slip lining is a 7-step process from start to finish, often taking only a couple of days to complete. Let’s walk through it.

Inspect the Pipe: check the host pipe to assess damage, build up, or other issues that should be considered prior to starting the installation.

Clean the Pipe: using water jetting or pigging to clean out clogs, debris, build up, and obstructions. The host pipe needs to be thoroughly cleaned to guarantee a proper seal between the host and carrier pipes.

Join the Carrier Pipes: join sections of the carrier pipe together to meet the required length of the repair.

Access the Existing Host Pipe: Excavate at the entry and exit points of the repair.

Install the Liner: Either push or pull the carrier pipe through the host pipe, depending on the carrier pipe’s material and joint type (HDPE can be pushed or pulled, but bell-and-spigot joint pipes need to be pushed to keep a watertight seal).

Restore Lateral Connections: after the 24-hour relaxing period, reconnect any lateral pipes with saddles.

Restore Terminal Connections: Stabilize the carrier pipe within the host pipe by filling the gap with grout. After the grout is cured, reconnect the existing terminals to the host pipe with appropriate fittings.

Benefits

Slip lining comes with some considerable benefits, ranging from cost to convenience. These are the biggest advantages of choosing this type of trenchless pipe relining:

Lower cost than most conventional repairs and some trenchless methods

Less digging than conventional methods

Less time from start to finish than trenched repairs

Extended life use expectancy, anywhere from 50 to 100 years

Drawbacks

But, with around 80 years of advancement since its invention, slip lining also has several drawbacks, many of which newer methods have improved upon or solved:

Slip lining does not work well for smaller diameter pipes, and generally isn’t possible for residential repairs

Longer downtime than other trenchless methods available

Reduces flow capacity, especially in smaller diameters

Requires straight runs because the carrier pipe is not flexible enough for turns

Not suitable for severely damaged pipes since it requires the host pipe’s structure for support

Deformities in the pipe will prevent slip lining

More invasive than other trenchless techniques

Improper grouting can result in pipe collapse

How Does Slip Lining Compare to CIPP Lining?

Now that we’ve covered the slip-lining process let’s take a quick look at CIPP lining. CIPP, or cured-in-place pipe, uses resin to form a new pipe inside the existing damaged pipe. Inversion relining, where a resin-saturated liner is pushed into a pipe through air or water pressure, takes only hours to complete.

The curing process can take anywhere from a couple of hours to a day using ambient curing or steam-cured epoxies. But modern advancements provide a UV light curing method that requires less than five minutes to complete. That means that from start to finish, you may only need a half day’s work to get your customers back to normal.

The cost is often a little more than slip lining, but with as many as three days for slip lining to complete, it’s much faster. Depending on your customers and their specific needs, the additional cost may be worth the convenience.

But slip lining versus CIPP lining is also a matter of the type of jobs you anticipate for your business. Here are three key areas to consider before choosing one over the other.

CIPP vs Slip Lining for Minor Leaks or Damage

CIPP relining and slip lining both work well for minor leaks and less comprehensive damage, although they won’t work on the same pipe sizes. Since both are less invasive than conventional repair methods, the repairs take less time to complete. For larger diameters, slip lining is ideal. CIPP relining methods, since they have a thin profile, work better for smaller diameters, down to 2 inches.

CIPP vs Slip Lining for Major Breaks

Slip lining can repair minor to moderate issues, but the host pipe provides most of the structural integrity for the carrier pipe to stay free of leaks or further breaks. CIPP relining, in contrast, allows for more comprehensive damage repair. Pipes with more severe damage are still salvageable with CIPP since the liner conforms to the pipe’s shape and becomes rigid enough to support itself structurally.

CIPP vs Slip Lining for Sewer Line Repair

Slip lining is a viable option for sewer line repair, but it does require some excavation to complete. When there is no other access point to make the repair, the cost savings could outweigh the inconvenience of excavating. But if you have access points without excavating, such as somewhere within the building, CIPP lining becomes a better option. Not only does it avoid digging, but it also offers a faster turnaround time to complete. It may cost more, but it will mean getting back to normal faster.

| Slip Lining | CIPP Lining | |

|---|---|---|

| Excavation free | ✔ | |

| Short downtime | ✔ | ✔ |

| Sewer line repairs | ✔ | ✔ |

| Light to moderate damage | ✔ | ✔ |

| Large diameter pipes | ✔ | |

| Small diameter pipes | ✔ | |

| Severe damage | ✔ | |

| Curves and bends | ✔ |

Which Is Better, CIPP or Slip Lining?

The difference between CIPP lining and slip lining is cost versus convenience: slip lining is generally a less expensive option than most pipe relining or repair methods, but CIPP lining eliminates the excavation process and reduces the time from the start of repairs to completion. When either can be used, a decision needs to be made.

However, when choosing between slip lining and CIPP lining as a business investment, the decision is more focused on the range of applications and your customer base. Slip lining works well for large-diameter, non-residential applications. CIPP lining, on the other hand, is perfect for residential and multifamily uses that require working with smaller diameters for pipes.

If you’re planning to add a new pipe repair service to your plumbing company, or if you want to invest in a completely new business, CIPP relining for residential and multifamily repairs makes a quick return on that investment. The market for trenchless cured-in-place pipe relining grows every day as customers learn the benefits of the process. And as technology improves, the materials and equipment for CIPP repairs make the repairs faster and more effective.

At T3, we help you build a stronger plumbing company through the right technology, training, and materials to give you a new stream of customers without struggling to overcome the knowledge deficit that comes with new techniques. Contact us today to learn how we can get you started on the best trenchless repair systems for your business.